Publications

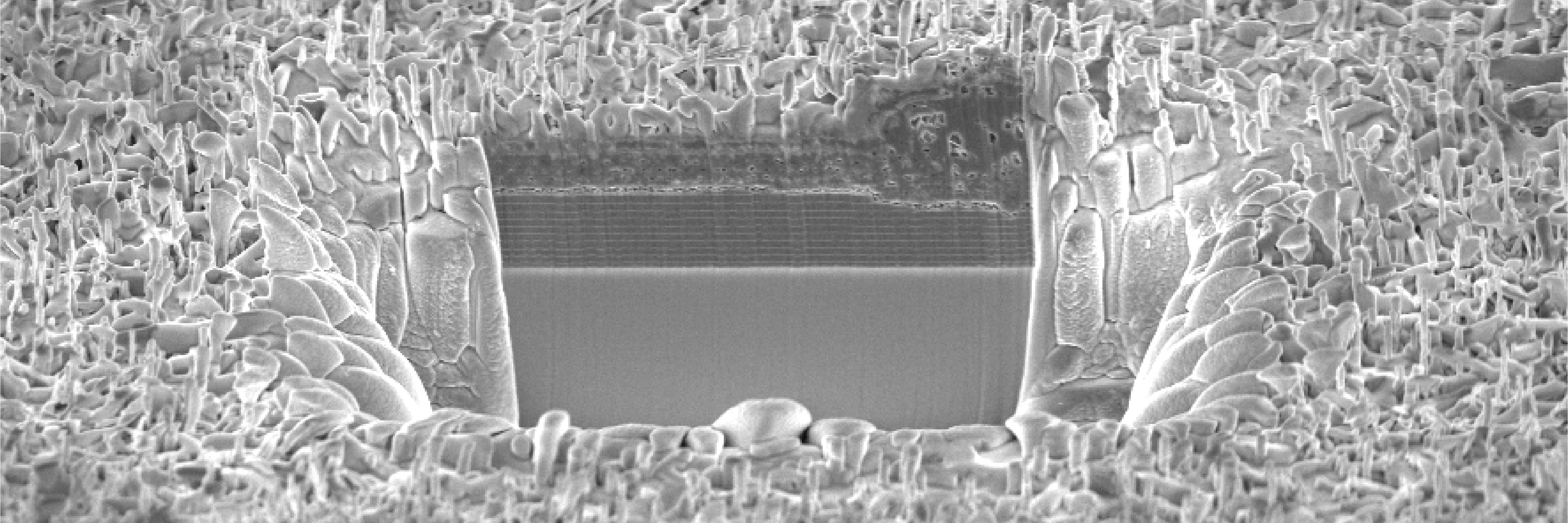

The outstanding oxidation resistance, thermo-mechanical stability, and chemical inertness of alumina, but also the synthesis of phase pure polymorphs attract particular attention in academia and industry. Especially, the difficulties regarding the synthesis of α- or γ-structured Al2O3 by physical vapor deposition techniques are still strong limitations. Within this study, we investigated in detail the influence of 2 at.% tungsten in the Al-target on the process stability and phase formation during reactive DC magnetron sputtering as well as high power impulse magnetron sputtering (HiPIMS) of Al2O3-based coatings. The small addition of W to the Al target allows to increase the oxygen partial pressure by more than 200 % while maintaining a stable deposition process. Ion mass spectroscopy measurements yield a promising high fraction of ¹⁶O⁺ and ³²O2⁺, when operating the W-containing target in the metal-to-poisoned transition mode. A significant increase of ¹⁶O⁺ is further provided by the target surface oxide in poisoned mode. Detailed time-of-flight ion mass spectroscopy investigations during one HiPIMS pulse show a clear temporal separation of the individual ions arriving at the substrate plane during the pulse on-time, allowing for controlled ion attraction by synchronizing the bias pulse to the discharge impulse. Equal amounts of ²⁷Al⁺ and ³²O2⁺ can be attracted using a bias on-time between 400 μs and 900 μs in the “off-time” (after glow) leading to a dense and nano-crystalline coating. Detailed electron microscopy investigations show the presence of metallic phase fractions for higher duty cycles (7.5 %). Decreasing the duty cycle to 3.75 % leads to amorphous coatings when operating the Al-target at the highest oxygen partial pressure in metallic mode.

Authors

S. Kagerer, L. Zauner, T. Wojcik, S. Kolozsvári, T. Kozák, J. Čapek, P. Zeman, H. Riedl, P.H. Mayrhofer

Journal

Surface and Coatings Technology