Publications

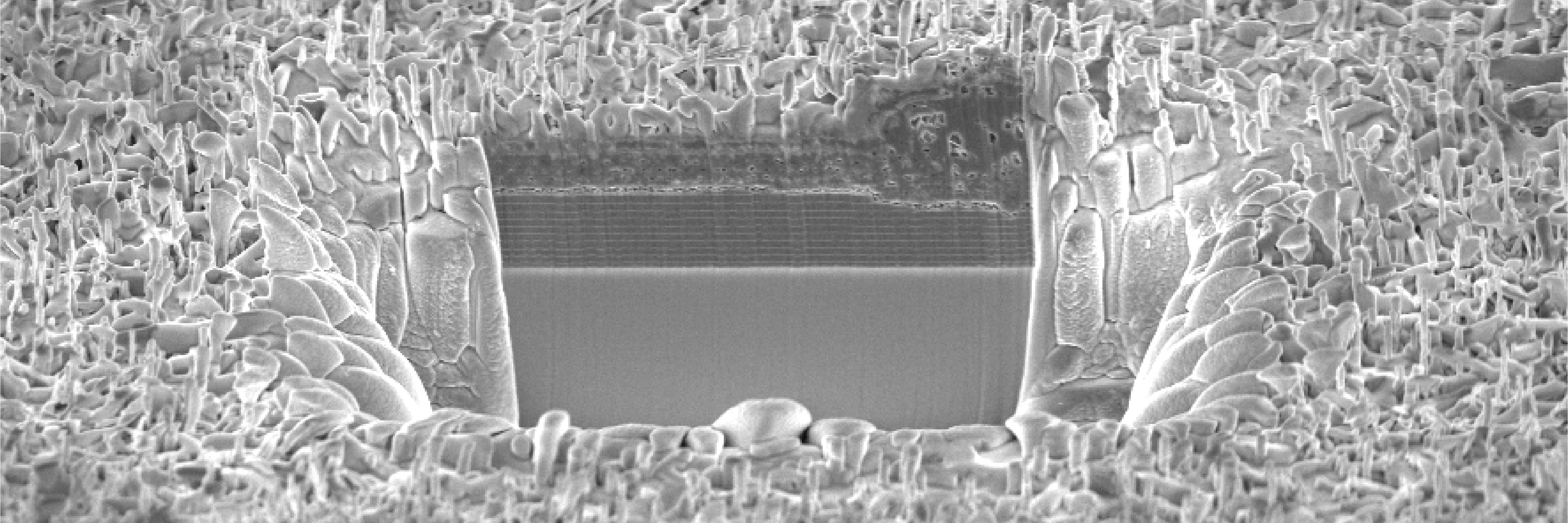

γ-TiAl alloys have gained much attention due to their low density, excellent fatigue resistance, and high specific strength at elevated temperatures. Throughout this study, we showcase physical vapor deposited Al-rich γ-TiAl coatings as a considerable solution to extend the durability and longevity of γ-TiAl bulk materials in high temperature regimes (> 750 °C). In detail, the oxidation resistance is enhanced up to at least 850 °C for 1000 h, whilst exhibiting a maximum oxygen affected area of 8.4 µm (16 µm coating). Based on various oxidation treatments (800, 850, and 900 °C), we estimated a mean parabolic rate constant of about 1.03∙10−10 cm²/h and a logarithmic oxygen inward diffusion rate of approximately 1.20∙10−4 cm/h. The corresponding activation energies validate the considerably retarded oxide scale kinetics – particularly, for the thermally grown oxides. Furthermore, the thermal exposure introduced excellent intermixing between the Al-rich γ-TiAl coating and γ-TiAl bulk material, resulting in a coalescence of the coating-substrate interface.

Authors

S. Kagerer, O. E. Hudaka, M. Schloffer, H. Riedl, P.H. Mayrhofer

Journal

Scripta Materialia