Publications

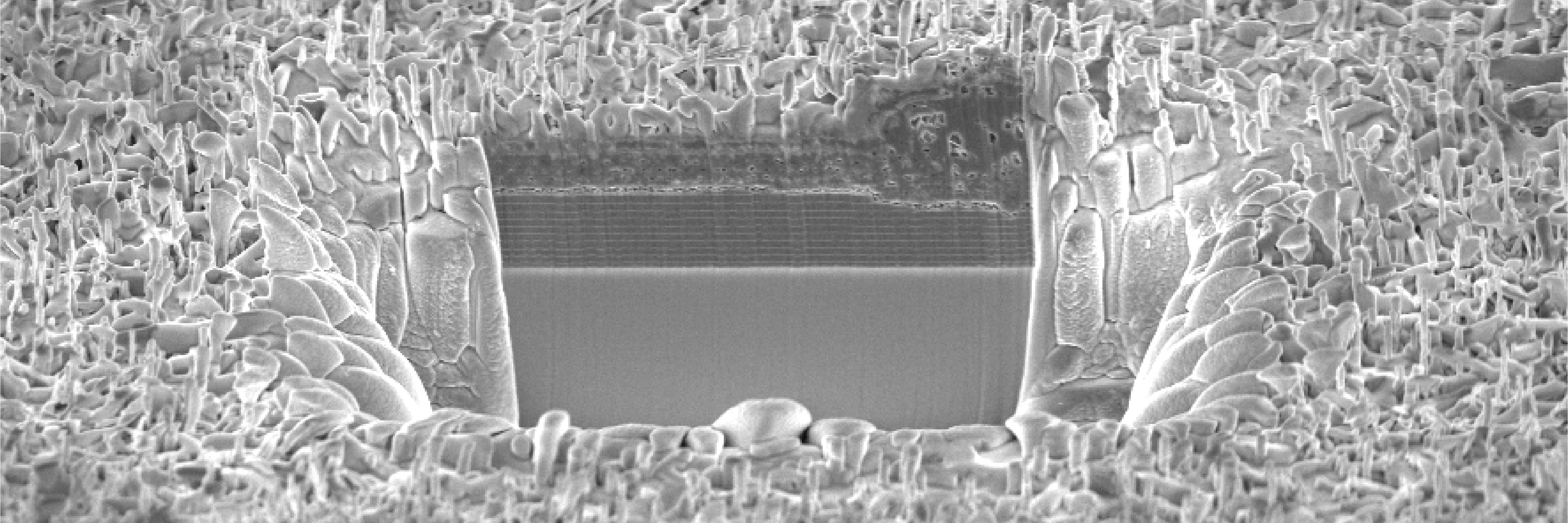

Reactive high-power impulse magnetron sputtering (R-HiPIMS) is seen as a key-technology for the deposition of future hard and multifunctional coatings. Increased ionisation rates allow for additional possibilities in tuning specific coating characteristics based on growth mechanisms varied by surface-diffusion. Especially within the well-established Ti-Al-N system, the Al solubility limit (xmax) of metastable face-centred-cubic (fcc) Ti1−xAlxN is an everlasting scientific topic. Here, we investigate in detail the dependence of xmax on various deposition parameters (i.e. pulse frequency and duration, N2-to-Ar flow rate ratio, and substrate bias potential) during R-HiPIMS of Ti-Al-N coatings using Ti0.6Al0.4, Ti0.5Al0.5 and Ti0.4Al0.6 composite targets. The systematic studies showed that the highest solubility limit of xmax ∼0.55 could be obtained for duty cycles around 3.75% (peak power densities of ∼1.0 kW/cm2) and a N2-to-Ar flow rate ratio of 0.3. A further decisive fact for the deposition of high Al containing fcc-structured Ti1−xAlxN coatings is surface diffusion controlled by bias potentials (DC as well as modulated pulses) ensuring sufficient intermixing of the arriving film species. Despite the presence of very small amounts of wurtzite-typed phases, excellent hardness values of ∼36 GPa for Ti0.40Al0.60N – which further increased to ∼ 40 GPa upon annealing for 1 h at 700 °C – could be achieved for a DC bias potential of -50 V, irrespective of all variations conducted. Based on our results we can further conclude, that the ratio and energy of Tin+- and Aln+-ions, simultaneously arriving at the substrate surface, are decisive for stabilising the highly preferred cubic modification. A distinct promotion of specific discharge regimes – selected by synchronised bias pulses – can thus positively influence the cubic phase formation through altered gas-to-metal ion ratios arriving at the film surface.

Authors

L. Zauner, Ph. Ertelthaler, T. Wojcik, H. Bolvardi, S. Kolozsvári, P. H. Mayrhofer, and H. Riedl

Journal

Surface and Coating Technology