Publications

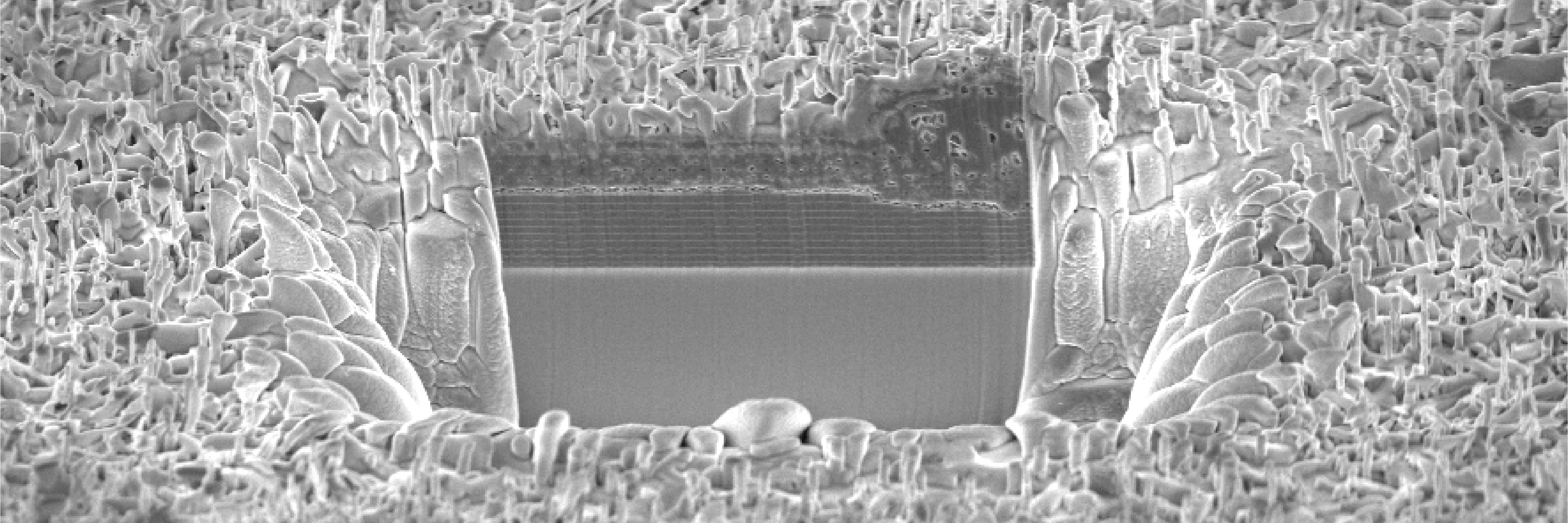

Hard protective coating materials based on transition metal nitrides and carbides typically suffer from limited fracture tolerance. To further tune these properties non-metal alloying – substituting C with N – has been proven favorable for magnetron sputtered Hf-C-N based thin films. A theoretically predicted increase in valence electron concentration (from 8.0 to 9.0 e/f.u. from HfC to HfN) through nitrogen alloying lead to an increase in fracture toughness (KIC obtained during in-situ SEM cantilever bending) from 1.89 ± 0.15 to 2.33 ± 0.18 MPa·m1/2 for Hf0.43C0.57 to Hf0.35C0.30N0.35, respectively. The hardness remains close to the super-hard regime with values of 37.8 ± 2.1 to 39.9 ± 2.7 GPa for these specific compositions. Already the addition of small amounts of nitrogen, while sputtering a ceramic HfC target, leads to a drastic increase of nitrogen on the non-metallic sublattice for fcc single phased structured HfC1-xNx films, where x = N/(C + N). The here obtained results also provide experimental proof for the correlation between fracture characteristics and valence electron concentration.

Authors

T.Glechner, S.Lang, R.Hahn, M.Alfreider, V.Moraes, D.Primetzhofer, J. Ramm, S.Kolozsvári, D.Kiener, H.Riedl

Journal

Surface and Coating Technology