Publications

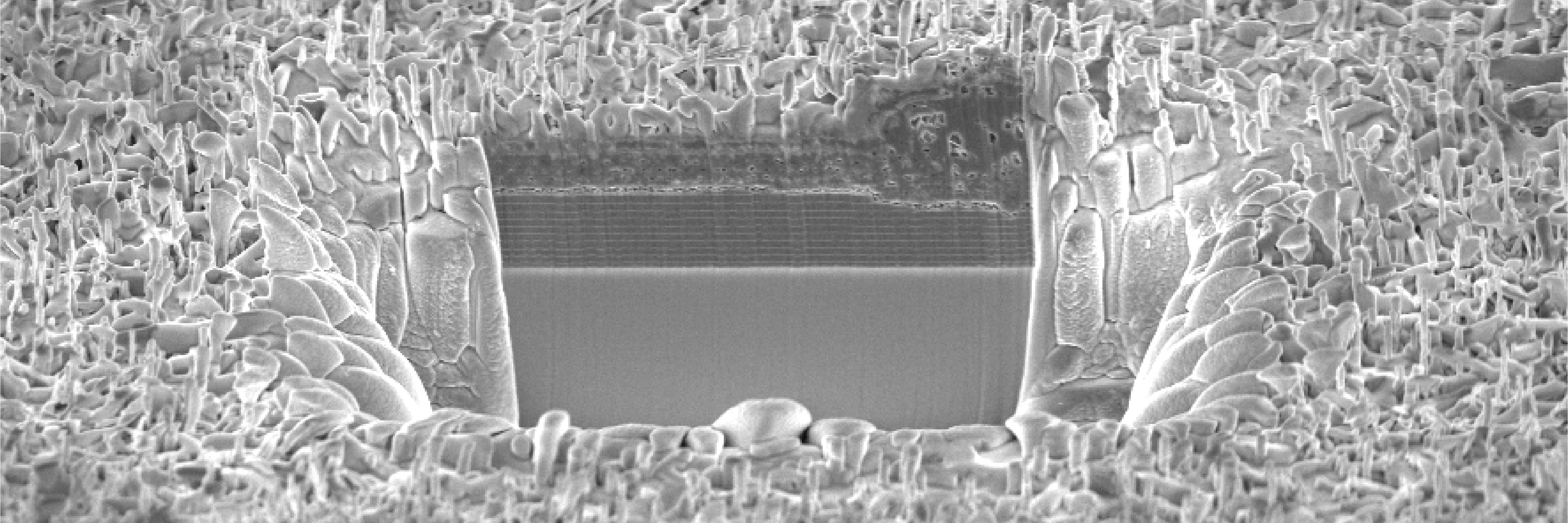

Cathodic arc evaporated Ti1−xAlxN coatings were deposited on a Nimonic c-263 superalloy and tested under low temperature hot corrosion conditions. Treated with a MgSO4/Na2SO4 salt-mixture, all samples were annealed at 700 °C in a 2800 ppm(volume) SOx-rich atmosphere for 1, 5, 15 and 30 h. A significantly reduced corrosion severity was exhibited by all Ti1−xAlxN variants over the uncoated NiCrCo alloy. A synergistic fluxing mechanism was found to be the dominant factor for the coating breakdown. Depending on the relative Al-to-Ti content on the Ti1−xAlxN sublattice, differences in the coatings’ corrosion and scaling behavior were observed.

Authors

O.E. Hudak, A. Scheiber, P. Kutrowatz, T. Wojcik, L. Shang, O. Hunold, S. Kolozsvári, P. Polcik, H. Riedl

Journal

Corrosion Science