Publications

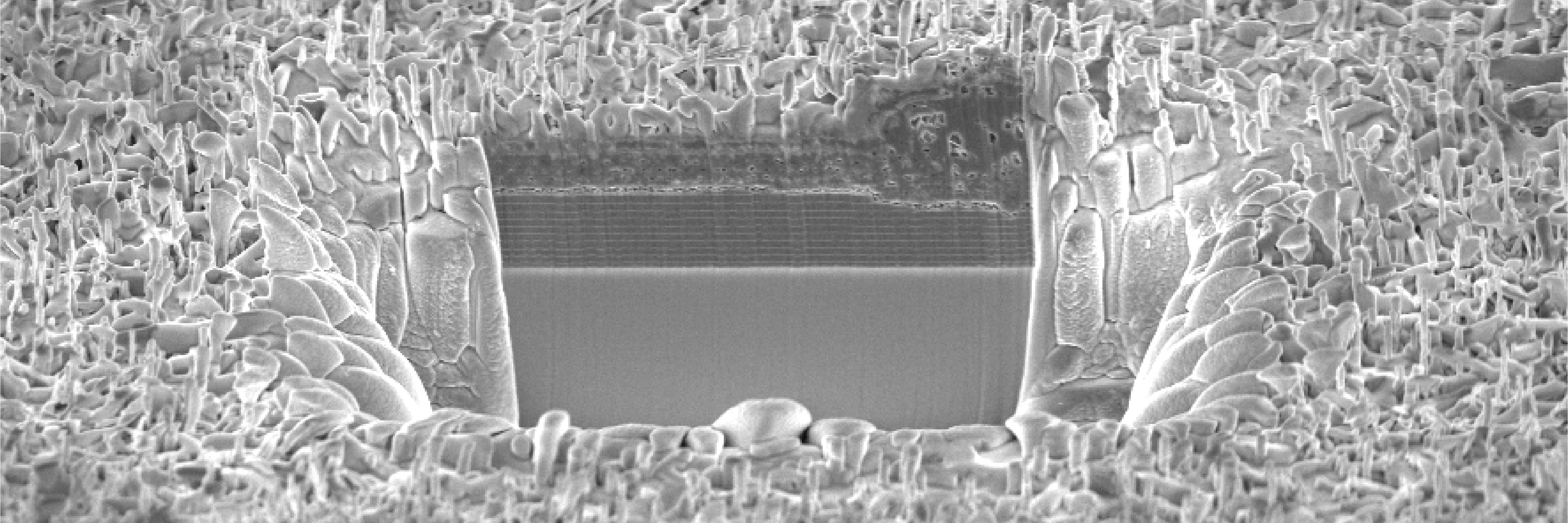

In the field of hard protective coatings, nano-crystalline Ti-B-N films are of great importance due to the adjustable microstructure and mechanical properties through their B content. Here, we systematically study this influence of B on Ti-B-N during reactive as well as non-reactive DC magnetron sputtering. The different deposition routes allow for an additional, very effective key parameter to modify bond characteristics and microstructure. Plasma analysis by mass spectroscopy reveals that for comparable amounts of Ti+, Ti2+, Ar+, and Ar2+ ions, the count of N+ ions is about 2 orders of magnitude lower during non-reactive sputtering. But for the latter, the N+/N2+ ratio is close to 1, whereas during reactive sputtering this ratio is only 0.1. This may explain why during reactive deposition of Ti-B-N, the Bsingle bondN bonds dominate (as suggested by X-ray photoelectron spectroscopy), whereas the Bsingle bondB and Tisingle bondB bonds dominate for non-reactively prepared Ti-B-N. Chemically, reactively versus non-reactively sputtered Ti-B-N coatings follow the TiN-BN versus TiN-TiB2 tie line, respectively. Detailed X-ray diffraction and transmission electron microscopy studies reveal, that up to 10 at.% B can be dissolved in the fcc-TiN lattice when prepared by non-reactive sputtering, whereas already for a B content of 4 at.% a BN-rich boundary phase forms when reactively sputtered. Thus, we could not only observe a higher hardness (35 GPa instead of 25 GPa) as well as a higher indentation modulus (480 GPa instead of 260 GPa), but also a higher fracture energy (0.016 instead of 0.009 J/m during cube-corner indentations) for Ti-B-N coatings with 10 at.% B, when prepared non-reactively.

Authors

R. Hahn, A. Tymoszuk, T. Wojcik, A. Kirnbauer, T. Kozák, J. Capek, M. Sauer, A. Foelske, O. Hunold, P. Polcik, P.H. Mayrhofer, H. Riedl

Journal

Surface and Coatings Technology