Publications

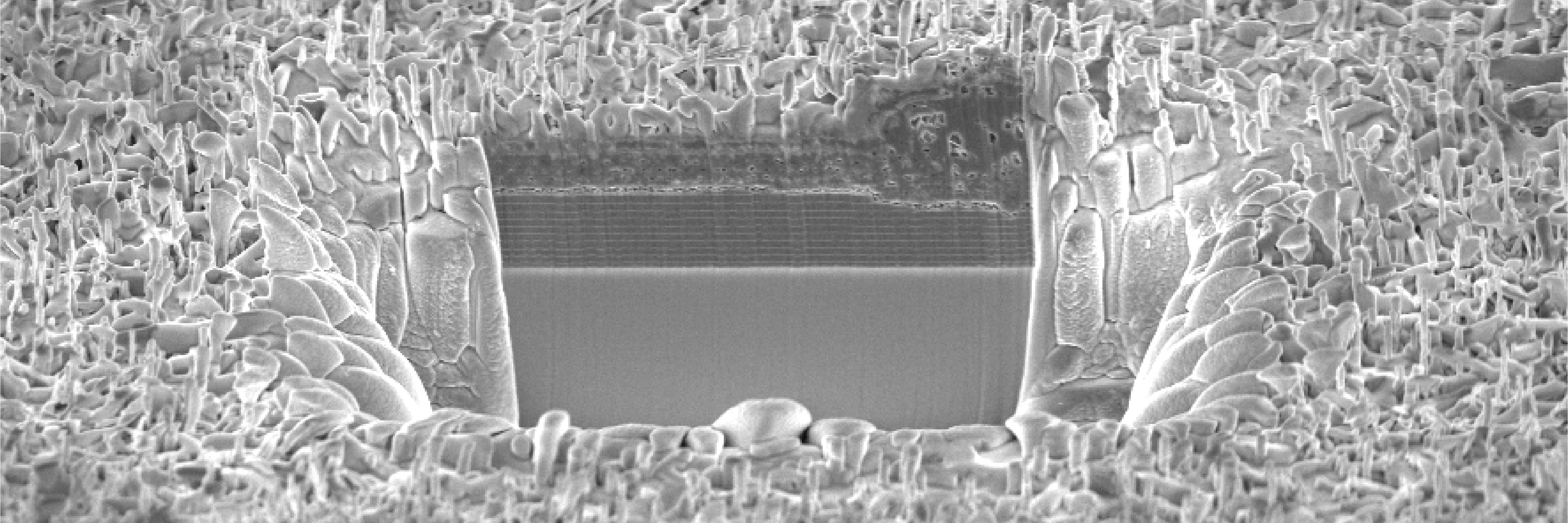

This work investigates the influence of Si-alloying up to 17 at.% on the structural, mechanical, and oxidation properties of magnetron sputtered CrB2±z-based thin films. Density-functional theory calculations combined with atom probe tomography reveal the preferred Si occupation of Cr-lattice sites and an effective solubility limit between 3 to 4 at.% in AlB2-structured solid solutions. The addition of Si results in refinement of the columnar morphology, accompanied by enhanced segregation of excess Si along grain boundaries. The microstructural separation leads to a decrease in both film hardness and Young’s modulus from H ~ 24 to 17 GPa and E ~ 300 to 240 GPa, respectively, dominated by the inferior mechanical properties of the intergranular Si-rich regions. Dynamic thermogravimetry up to 1400 °C reveals a significant increase in oxidation onset temperature from 600 to 1100 °C above a Si content of 8 at.%. In-situ X-ray diffraction correlates the protective mechanism with thermally activated precipitation of Si from the Cr-Si-B2±z solid solution at 600 °C, enabling the formation of a stable, nanometer-sized SiO2¬¬-based scale. Moreover, high-resolution TEM analysis exposes the scale architecture after dynamic oxidation to 1200 °C (10 K/min heating rate) – consisting only of ~20 nm amorphous SiO2 beneath ~200 nm of nanocrystalline Cr2O3. In summary, the study provides detailed guidelines connecting the chemical composition with the respective thin film properties of high-temperature oxidation resistant Cr-Si-B2±z coatings.

Authors

L. Zauner, A. Steiner, T. Glechner, A. Bahr, B.Ott, R. Hahn, T. Wojcik, O. Hunold, J. Ramm, S. Kolozsvári, P. Polcik, P. Felfer, H. Riedl

Journal

Journal of Alloys and Compounds